Our Bi-metallic Lugs and connectors are made from the Highest Quality Electrolytic Grade Copper & Aluminum which are joined using a friction welding process. The barrels are chemically treated to reduce resistance & corrosion.

The most crucial process in the manufacturing of bimetallic lugs is friction welding and our in-house friction welding machine is CNC controlled and is second to none. The advantage of our machine is that the turning attachment first takes a light cut on the copper palm on the machine itself which minimizes atmospheric oxidation thus resulting in a very sound weld joint. Apart from this the entire machine is PLC Controlled and has servo-controlled motors, this results in strict parameter control again resulting in a sound weld joint.

Material: ETP Copper & Aluminum

Finish: Natural

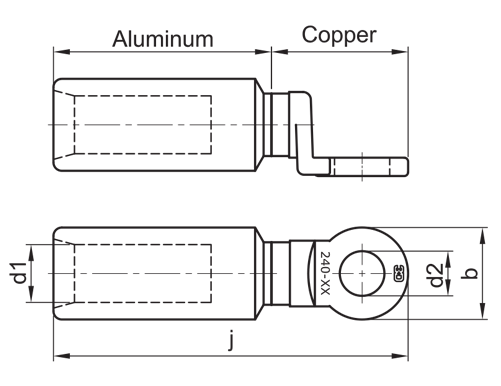

| Technique Data | |||

|---|---|---|---|

| 3D Cat. No | j | Ø d1 | b |

| 3D BL 6-XX | 75 | 3.5 | 20 |

| 3D BL 10-XX | 75 | 4.5 | 20 |

| 3D BL 16-XX | 75 | 5.5 | 20 |

| 3D BL 25-XX | 75 | 7.5 | 20 |

| 3D BL 35-XX | 75 | 8.5 | 20 |

| 3D BL 50-XX | 75 | 9.5 | 24 |

| 3D BL 70-XX | 75 | 11.5 | 24 |

| 3D BL 95-XX | 115 | 13.5 | 24 |

| 3D BL 120-XX | 115 | 15.5 | 30 |

| 3D BL 150-XX | 120 1 | 6.5 | 30 |

| 3D BL 185-XX | 120 | 18.5 | 35 |

| 3D BL 240-XX | 135 | 22 | 35 |

| 3D BL 300-XX | 135 | 23.5 | 36 |

| 3D BL 400-XX-B | 145 | 26 | 36 |

| 3D BL 400RT-XX | 160 | 26.5 | 50 |

| 3D BL 500RT-XX | 160 | 30 | 50 |

| 3D BL 500-XX" | 160 | 30 | 50 |

| 3D BL 630-XX* | 175 | 34 | 60 |

| *Rectangle Palm | |||

Notes:-

Corrossion Inhibiting Grease on request

Material - ETP Copper and Aluminum

Finish - Natural

In Cat. No. XX denotes Stud Size

If specified, hole to be punched in accordance with Table1. Part number to denote suffix of bolt size. Eg 3D BL 70-12

The drawing is only a representation of the actual Product, and hence may not look exactly like the final Product

All Dimensions indicated in the catalogue are nominal dimensions, Product produced may vary in size within the Stipulated Tolerance

*Symbol for Square type palm

| Nom. Bolt Size | Dia d2 |

|---|---|

| M6 | 6.5 |

| M8 | 8.5 |

| M10 | 10.5 |

| M12 | 13 |

| M14 | 15 |

| M16 | 17 |

| M20 | 21 |

Material: ETP Copper & Aluminum

Finish: Natural

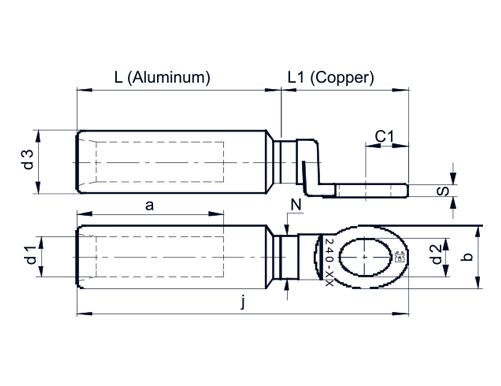

| Technique Data | ||||

|---|---|---|---|---|

| 3D Cat. No. | j | Ø d1 | b | |

| ±4 | ±0.2 | ±1 | ||

| 3D BL | 6-XX | 75 | 3.5 | 20 |

| 3D BL | 10-XX | 75 | 4.5 | 20 |

| 3D BL | 16-XX | 75 | 5.5 | 20 |

| 3D BL | 25-XX | 75 | 7.5 | 20 |

| 3D BL | 35-XX | 75 | 8.5 | 20 |

| 3D BL | 50-XX | 75 | 9.5 | 24 |

| 3D BL | 70-XX | 75 | 11.5 | 24 |

| 3D BL | 95-XX EC | 95 | 13.5 | 24 |

| 3D BL | 120-XX EC | 106 | 15.5 | 24 |

| 3D BL | 150-XX EC | 107 | 16.5 | 24 |

| 3D BL | 185-XX EC | 114 | 18.5 | 30 |

| 3D BL | 240-XX EC | 119 | 22 | 30 |

| 3D BL | 300-XX EC | 123 | 23.5 | 35 |

| 3D BL | 400-XX EC | 145 | 26 | 36 |

| 3D BL | 500-XX EC | 141 | 30 | 36 |

| 3D BL | 630-XX EC | 160 | 34 | 50 Sq |

Notes:-

Corrossion Inhibiting Grease on request

Material ETP Copper and Aluminum

Finish - Natural

In Cat.No. XX denotes Stud Size If specified, hole to be punched in accordance with Table1. Part number to denote suffix of bolt size. Eg 3D BL 70-12

The drawing is only a representation of the actual Product, and hence may not look exactly like the final Product

All Dimensions indicated in the catalogue are nominal dimensions, Product produced may vary in size within the Stipulated Tolerance

*Symbol for Square type palm

| Nom. Bolt Size | Dia d2 ±0.25 |

|---|---|

| M6 | 6.5 |

| M8 | 8.5 |

| M10 | 10.5 |

| M12 | 13 |

| M16 | 17 |

| M20 | 21 |